Why Do So Many Steel Shapes Exist?

Steel profiles aren't random. They're designed to handle load, force, pressure, and bending in different ways. A tall skyscraper needs a beam that can resist vertical compression. A platform frame needs a shape that can handle bending. Machinery needs a profile that is easy to weld and work with.

Each shape—H-Beam, I-Beam, U-Channel, Angle Iron—is a solution to a specific problem.

If you choose the wrong profile for the job:

- Too much bending: The structure may sag or deform.

- Weak connections: Welds and joints may fail under load.

- Unnecessary weight: Costs go up with no benefit.

- Structural instability: Worst case — dangerous failure.

Understanding these shapes helps you pick the right one, avoid costly mistakes, and build safer, longer-lasting structures.

H-Beams: The Heavy Lifters

H-Beams are known for their wide flanges and massive load-bearing power. Their thick horizontal plates and strong vertical web create a shape that distributes force evenly, making them ideal for heavy construction.

Where H-Beams Shine:

- Columns in multi-story buildings

- Bridge supports

- Industrial foundations

- Platforms and heavy load frames

H-Beams are chosen when strength isn't just important—it's mandatory. Their wide shape resists bending, twisting, and crushing forces better than almost any other profile.

I-Beams: Precision Strength for Long Spans

I-Beams look similar to H-Beams but have narrower flanges, making them lighter and more efficient for specific applications. They provide incredible strength-to-weight ratio, which is why they're used in long spans and elevated structures.

Where I-Beams Are Best:

- Roof beams

- Floor joists

- Elevated walkways

- Structural spans with limited weight

Their shape concentrates steel where it's needed most—top and bottom—letting them handle bending without adding unnecessary mass.

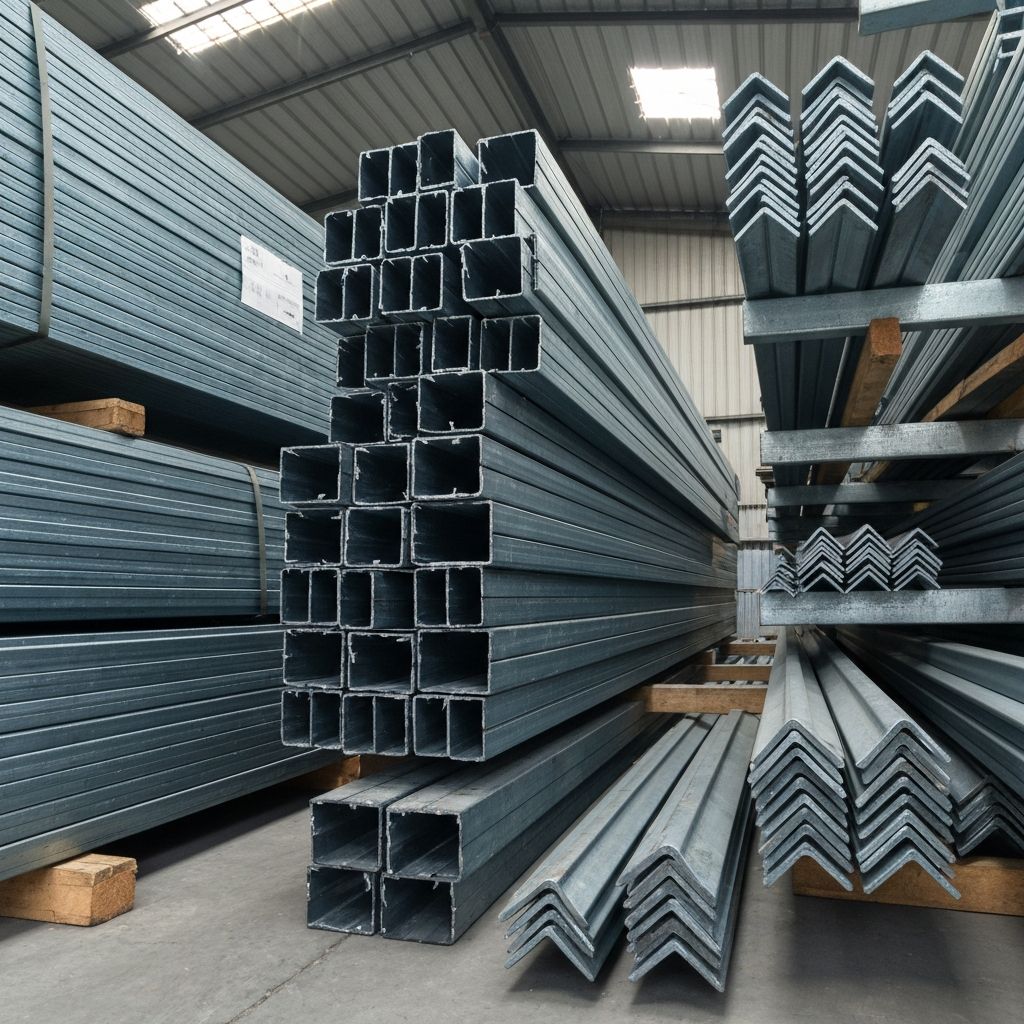

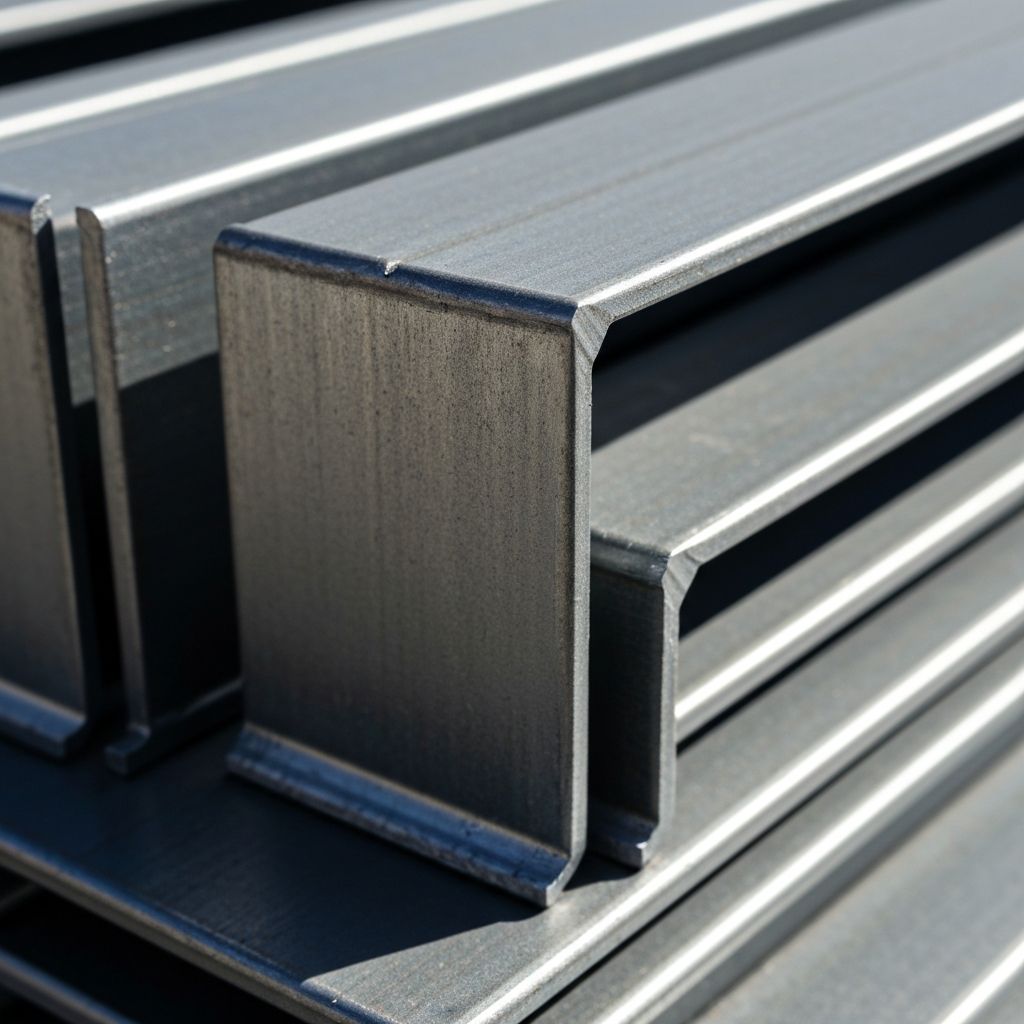

U-Channels and Angle Iron

U-Channels, also called C-Channels, feature an open shape that makes them lighter and extremely versatile. They're often used for frames, supports, edges, rails, and custom fabrication.

What Makes U-Channels Useful:

- Easy to cut and weld

- Great for reinforcing edges

- Useful for machinery frames and automotive parts

- Perfect for lightweight structural components

Angle Iron is one of the simplest and most widely used steel shapes. Its L-shaped design allows it to support weight along two planes, making it ideal for bracing, framing, and reinforcing corners.

Common Uses for Angle Iron:

- Shelving and racks

- Stair frames

- Wall bracing

- Corner reinforcement

- Smaller structural builds

Why Choosing the Right Profile Matters

Every steel shape has a purpose. Using the wrong one can lead to performance issues, weak joints, unnecessary weight, or even structural danger. Engineers calculate these choices carefully because each profile handles stress differently.

Key differences include:

- How the profile handles bending

- Where the load is concentrated

- How it performs under compression

- Weight vs strength efficiency

- Ease of welding or connecting

Even small differences in flange width, web thickness, or shape can dramatically change a structure's performance.